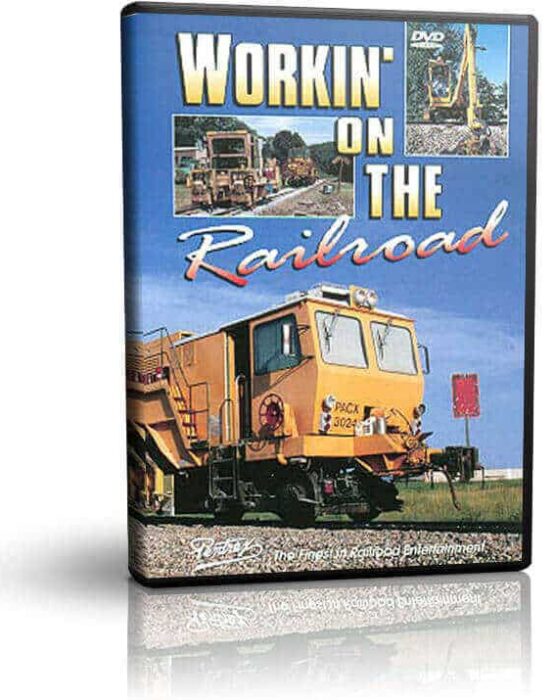

Working on the Railroad

SKU: DVD-PNX-WOTROriginal price was: $29.95.$24.95Current price is: $24.95.

Have you ever passed a track gang and wondered what all those machines actually do? Here’s your answer and more.

In stock

- Free Post Office shipping over $25!

- Free UPS shipping over $75!

| Producer | Pentrex |

|---|---|

| Run Time | 1 hour 35 minutes |

| Narration | Yes |

| Shrink Wrap | Yes, Brand New |

| Technical Details | NTSC, Region Free, View Worldwide on Computer |

Have you ever passed a track gang and wondered what all those machines actually do? Here’s your answer and more. You’ll visit a tie replacement and surfacing gang to witness the amazing parade of equipment as it progresses down the track. Close-up shots explain what each machine does. Then you’ll tour a major shop to see in detail how coal hoppers are built. Next you’re off to view undercutting machines cleaning ballast on BNSF.

Did you ever wonder what it’s like to work as a dispatcher? You’ll visit a Norfolk Southern facility where the chief dispatcher explains the operation. Returning to BNSF, you’ll see one of the most awesome pieces of railroad equipment: the P-811 concrete tie layer. This gigantic device lifts welded rails from the ties and forces them to both sides of the machine. It then removes old ties from the right of way, replaces them with new ones, and puts the rails back in place, all in one continuous movement. It’s an absolutely fascinating, complex apparatus. You’re sure to enjoy this and all of the other exotic equipment Workin’ on the Railroad!

rickyfreni –

In this hard to imagine it’s already 20 years old Videotape, the program starts with stock footage from Sacramento railfair 1991 that had special effects to resemble the Gandy dancers, then the main focus starts with a modern work gang number 1: the Timber and surface gang is working across southern Illinois on Norfolk Southern’s double track mainline. The crane is moving new ties to the side of the track, and would later pick up the worn out types. Next, a quartet of spike pullers comes along as they are removing the spikes from both inside and outside of the tracks. Afterwards, the old spikes are picked up, and are replaced by new ones with a machine called the spike loader. A quartet of magnetic wheels pick up the spikes. Later on, the process continues with the anchor spreader. A look down the line shows more machines at work. In the foreground, is the tie removal machine. Behind that, are a pair of tie cranes, then comes the other crane installing the new ties. The other crane that installs and exits the ties are called the tie puller. Behind the tie puller, 2 boys are using long hooks to move the plates out of the way. Next, the tie cranes picked up some of the old ties and puts them on a flatbed. The flatbed could handle 16 ties. Once loaded, the man bangs them with metal strapping, then dumps them along side to be picked up later. Minutes later, another tie crane follows behind, this time it is setting up some new ties. It is revealed that this location is at New Baden Illinois. A pair of tie Inserters are included as they are getting ready for loading the new ones in the track. Following behind the twin tie inserters, a tie plate broom is shown as it is getting ready to clean some rocks and debris off the ties. A man uses a hook to handle one side of the track. Behind the broom, is the manually operated tie plate inserter. Hooks are used to avoid back bending, finger and toe losing for the workmen. The machine only jacks the rail. Afterwards, a pair of automatic spike drivers are responsible to install the new spikes. Sometimes it must come to a stop to let the reloading process continue. Behind the spike drivers, a manual spike driver is shown, but there is an error in the title profile. It is spelled as a Human’s name. Afterwards anchor placers are included which is also manually operated. Then comes the anchor machine. When working for the railroad outdoors, the men must do these things in truck trailers just like the military. The eat, sleep, shower, and watch tv. A man is making some soup in the kitchen trailer. A pile Of thawing steaks would be used for the evening meal. Next to the kitchen is the dining hall. Back outside, the ballast regulator is shown to install New ballast to the track the next morning. A Quartet Of Ballast tampers would be used to squeeze ballast under the tracks. Meanwhile a regular train is shown: a westbound Norfolk Southern freight number 112 led by G5F number 6644, and a pair of standard cab C40-8 units numbers 8749 and 8828. The tampers must tamp every other tie. The end of the freight clears as the tampers and regulators went back to work. The second tamper is just working on every third tie. Tamper number 3 is shown as well as the anchor masher. Behind the tamper, is a man who checks for any problems on anchors and spikes. Ballast regular number 1 comes into view as it would make several trips back and forth. The second ballast regulator comes into view as well. Note the front end loader crossing the tracks. The side blades smooth out some of the lumps along the way. Afterwards the unit brooms the rocks as it heads in reverse. The last machines to get the track reopen again comes into view. They are called the track brooms. One machine picks up most of the rock from between the rails, the other smooths out the mess. With the track work finished, a hi-rail inspection vehicle uses a crane and trailer to pick up the old bundle ties in groups of 16.

Heading east, stock footage from Norfolk Southern’s Pocahontas district is used as a pair of standard cab C40-8 units numbers 8673 and 8595 are on an empty coal train in West Virginia. A look at the top gon car rebody program is shown at Roanoke, home of J class 611 and A class 1218. Fun fact alert: this 1999 video says that NS rebuilt 17,052 hopper cars. Car 31103 rolled out of the paint shop. This visit was made in July of 1995, during production of NS’ Pocahontas district and the rathole. The old cars are stripped down, and then hauled to the assembly shop. Trucks are also rebuilt as well as the center beams. Warning sirens sound to alert the workers. The first stops are at the assembly line. The center stills will be moved from their trucks and be placed in their ship bogeys. Then comes the male center castings, the coupler pockets are prepared, as well as more rust removing and overhead cranes are used to move the bases of the cars. After welding, the cars are moved to the next station. One of the parts from the hopper car lowers it into position. Welding will take place at another station. The car is placed on shop bogeys again. The line moves forward as side panels are built in a giant press. 2 men work with massive drills. Welders are being used near the end of the assembly line. 2 wire fed arc welders are used to make the job go faster. At the far end of the building, the crane picked up the side panel. The crane lifts the panel up high, where it will be attached to the car. A rivet is placed in a pre-drilled hole. At the transfer table, cars are moved to the return portion of the line. More welding must be done, as well as installing wheels, couplers, brake pipes, and also an inspection before the paint installation. Another siren is heard in the background. Each truck is used to take a spin at a small turntable. Soon the crane installed the car body to the wheels, and then it heads for the paint shop. At the painting procedure, some people are used to apply the decals, the NS logo, and the numbering information to the car.

In 1998, BNSF undertook a major construction project on the Thayer Subdivision in Arkansas and Missouri. It was closed for 2 weeks. The undercutter machines are working on the line as the dirt and debris are removed from the ballast, then the chainsaw teeth grabs the mess leaving the track unbalanced. The concrete ties are suspended in the air. Notice the different level of track before and after the removal of the dirt. The vibrator separated good ballast form the dirt and debris. A different machine is cleaning ballast. The plows move the ballast inside the track. The material is moved from one car to the next through various belts, and the debris is moved from the conveyor boom. The second section of the machine is where the actual undercutter is located. The track is being raised as the ballast is being removed a first, then all of a sudden it returns to the rails. When the machine stopped for a break, a close up look at the teeth is shown. At last the debris is moved from the conveyor boom. Following behind the beast, 4 track machines are used to reshape the roadbed.

Afterwards, a 1990 visit to Mexico is shown as the examination of the time table tower operators in the old days. Modern dispatchers office is shown at blue field West Virginia in 1995 that was also shown during production of NS Pocahontas division. A really wide look at the map of the division is shown, plus an interview with Chief dispatcher Tom Johnson is shown, as well as an explanation of how a dispatcher operates and communicates with the crews of all NS trains on the telephone. Plus a dispatcher who refused to say his name, gave us a rundown of the Pocahontas district.

Returning to BNSF territory now, a look at the Concrete Tie Layer P-811. First some spike pullers are shown. Amazingly, concrete ties can live much longer than the old fashioned wooden ties. The old wooden ties are on flat cars led by a Blue and Yellow Santa Fe GP38R number 2303, and Burlington Northern GP39N 2807. The 2 diesels are responsible for pulling the P-811. Some wheel slipping is included. 2 gantry cranes are on flatbeds with special tracks, as it deposits wood ties on the flatbed. The other cranes are transferring the concrete ties to the big machine.

All in all, this is a great pentrex video to see what it was like to build and repair the tracks, visit a car body shop, as well as a tour of the dispatcher’s office. Plus there are some freights On Norfolk Southern as well.

T. Ross –

This is a great film about how those big machines worked on the railroad. Every bit of equipment is explained in detail and how it works. See the massive concrete layer at work and how it works. This machine is massive in size and how it works. See the recycle shop works, also see how the dispatch center is operated. A great film for the money.

Andy Weise –

There are plenty of videos even by pentrex of just run-bys. This is not that video. Mainly showing MOW Track work, Car Shop and my favorite which is the train dispatchers office. I would suggest buying it if you want to learn about railroad maintenance and management.

nssd60e –

See what it takes to keep the mainline running. See all the track equipment and hard work put in to keep Americas railroads running. A real neat video. Shows some cool mavhines

rrvideoman , Delisle Saskatchewan –

We have all seen the track gangs hard at work. They are slow and can tie up traffic. Most of us wonder about how this equipment actually works. This movie is the most complete and imformative video made on the working of the maintanance of the railroads. All the equipment and explainations is presented from start to finish. Very interesting. The final segment is the massive concrete tie layer. You have to see it to believe it. Amaizing. This machine is unlike any other made for railway maintanance. The video gives full details and excellent shots of the operations. Don’t forget the car rebuilding center. It’s a giant model shop using a bonding that is a little stronger that plastic glue. Recycling is big time here. We receive a real learning on how the main line railroads save some costs. On to see and learn the dispatch center. It may take a while to understand it all, but in the end we can understand how it is that so many trains can operate on on line all at the same time, without major problems. You need to be all eyes and have extreme patience to work in these offices. Well made presentation that receives high marks. A must for all the train video lovers and collectors.